Huatao Group was founded in 2008. We are a professional and leading

supplier of various rollers and gearbox for plastic & rubber,

pulp paper, corrugated board,nonwoven fabric industry with more

than 16 year experience.

Our products including rollers:

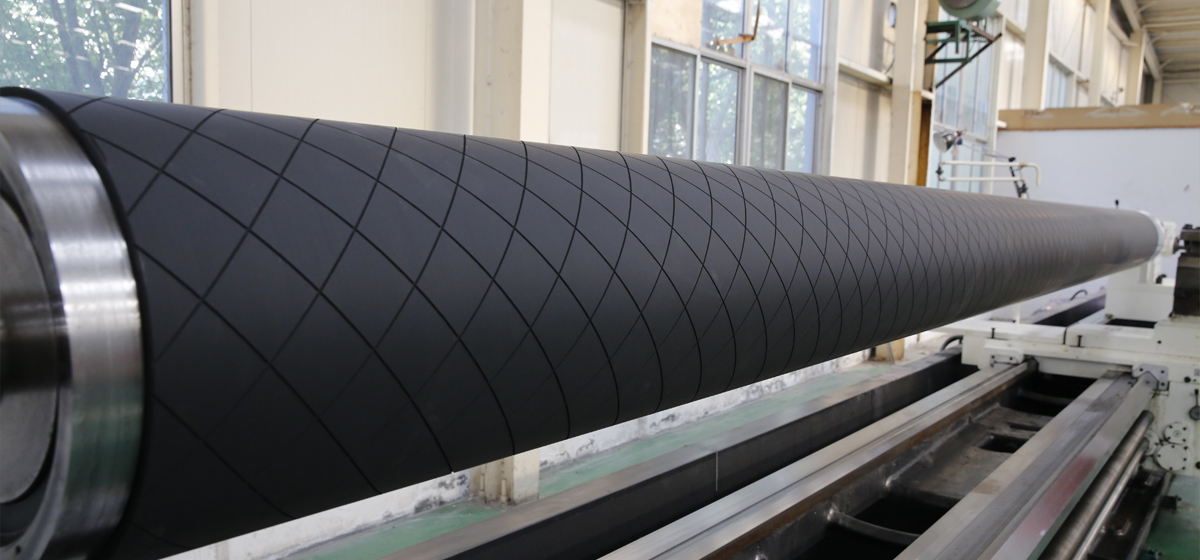

Plastic & Rubber industry: chill roller, MDO preheating roller, MDO

nip roller, MDO stretching roller, PRS cooling roller, corona

treater roller, corona treatment nip roller, flame treatment

roller, CFRP contact roller, CFRP tension roller, CFRP nip roller,

winding core, coating drum, cooling drum, spreader roller, anilox

roller, calender roller, embossing roller.

Paper Industry: forming roller, vacuum couch roller, dandy roller,

breast roller, rubber press roller, stone press roller, rubber

roller, dryer cylinder, size press roller, calender roller, pope

reel roller, spreader roller, embossing roller.

Nonwoven fabric industry: cylinder roller, doffer roller, CFRP

guide roller, embossing roller, cooling roller, spreader roller.

Gearbox:R series Gearmotor ,K series Gearbox,S series Gearbox,F

series Gearbox, Helical Bevel Gearbox, Planetary gearbox ,worm

gearbox

Due to we are the trading company, we know what’s customer concern

and focus on :always stable and superior quality, so our cooperated

factory must be first class in China ,which all have passing the

ISO system and also have the strict QC system, we learn about

factory’s advantages and can match with customer with superior

quality saving time,money and energy and help customer not walk

bend road,so these years we have wined many many customer’s visit

of HUATAO, here share you the picture.

Due to so many years customer accumulation and good customer

feedback , our roller and reducer have sold out to more than 120

countries and regions in the world, including: Germany, Japan,

Italy, Russia, Japan, South Korea, Turkey, Brazil , India, the

United Arab Emirates, Saudi Arabia and other countries, the

products are subject to a great welcome and praise.

Our goal :recommend the first class roller and reduce quality with

reasonable price to customer without walking bend road, as we all

know, one roller from one factory cannot meet your request, but we

can help you save communication time, purchasing costs and energy,

no matter what you demand, HUATAO is just professional with

offering you the best optimized solution.

For more detailed info on roller and reducer, feel free to contact

us ,HUATAO team is waiting for serve you with heart and soul, just

share the roller and reducer drawing you demand to get more better

quotation.